Across all sectors of industry, liquids are analysed, dosed, transported, changed and tempered in order to determine the composition of complex mixtures of substances and detect any occurring changes. Various processes are used for this, covering all scales – from piezoelectric micro valves to shipping locks. The requirements also vary depending on the size and application.

Requirements

The fluid control module focuses on mixing and monitoring different fluids – some with special properties – in a changing reactive environment. The systems must also be easy to switch with little specialist knowledge and without much effort.

- Tiny installation space

- Contactable control unit

- Media resistant

- Sensor/actuator hybrid

- UV resistant

Focus points

The following points are particularly important in order to support customers with their modular component landscape in this environment.

- Precise dosage

- Different media

- Fast reaction time

- Small installation space

- Fast switching

- Network capable

- Temperatures from -10°C to 125°C

While our customer takes care of the dosing technology and mechanics, binder provides the smallest possible control that can be integrated, including connection technology.

Solution

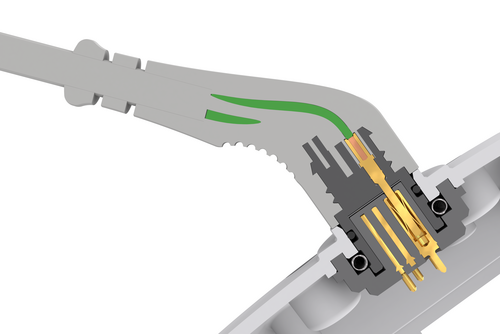

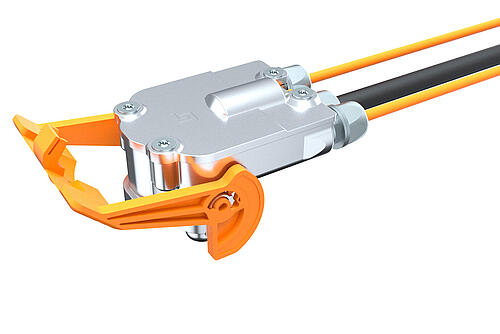

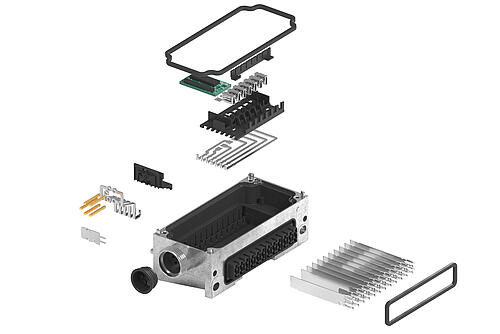

A three-layer sandwich assembly is integrated into a housing. It carries both the load of the actuator and the control functions. The control and load systems are thereby implemented in a hybrid solution that can target both focus points on different levels. This solution saves space and can be easily automated during industrialisation.

An adapted M12-based THT/SMT connector also enables quick and efficient connection of the contact technology in an incredible small space within a production line.

You provide the idea – we develop the best possible solution.

In the early phases of pre-development, binder solutions provides support for your project up until its completion. Our goal is to bring your product to market as quickly as possible. Thanks to our extensive value creation structure, we are able to utilise the wide-ranging competencies of the binder group and provide you with full-service support in every phase of the product development process. For optimal results, we use the latest methods and reliable manufacturing processes.

Our experts are able to develop appropriate laboratory tests up to and after series production, carry out component analyses and help you secure international approvals and release recommendations. Combined with our years of project management and design experience, we are able to respond iteratively to any changes as they come.

We look forward to the opportunity to demonstrate and win you over on the high quality and efficiency of our processes that are tailored to each customers’ needs.