E-mobility is essential for achieving long-term climate-neutral transportation. While a mixture of a fossil and an electric share is currently still advisable, the future belongs entirely to the strategy of all electric mobility. In addition, bidirectional charging will allow for a new system of battery networking in the future and thus enable modular solutions for transportation, domestic, as well as industrial applications. This will facilitate a distributed power supply and storage, which promises more safety, security, and convenience for the future.

New approach

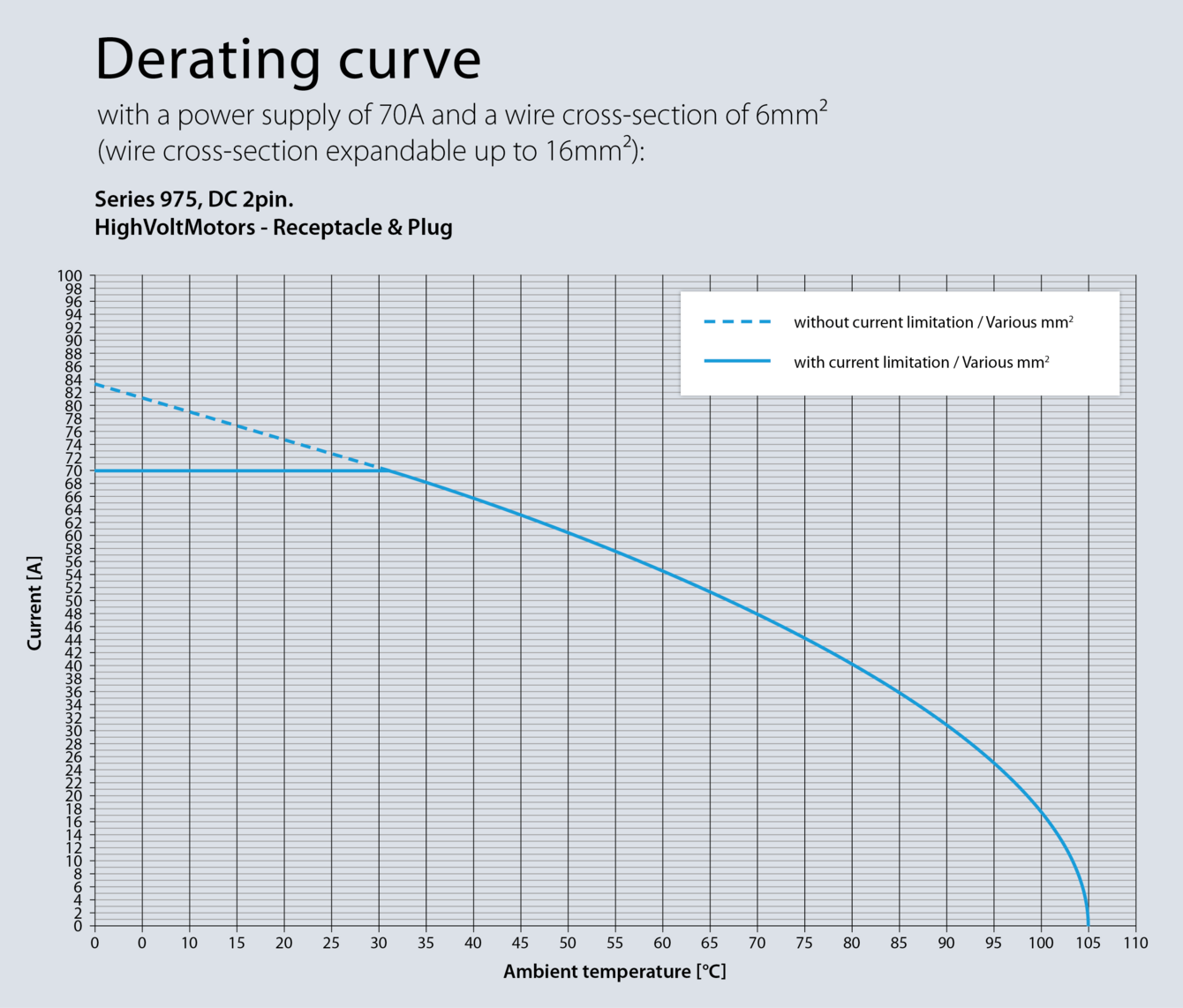

In the charging infrastructure, low-voltage applications for small vehicles such as pedelecs are used on the one hand, and high-voltage applications for the automotive sector on the other. Systems ranging from 12 V to 48 V and from 4 A to 20 A are often used for small vehicles. Automotive charging solutions that operate at higher voltages are equipped with the AC/DC system rated up to 350 kW of electrical power. In the future, solutions operating between 1 kW and 40 kW will be needed for battery-to-motor, battery-tocharging station, and battery-to-battery connections.

Our challenges

DC high-voltage charging systems are subject to high safety requirements. Misuse or improper operation can result in fires and even danger to life and limb.

At the same time, however, these systems must be easy and intuitive to operate so that people without any technical knowledge are able to use them.

Features

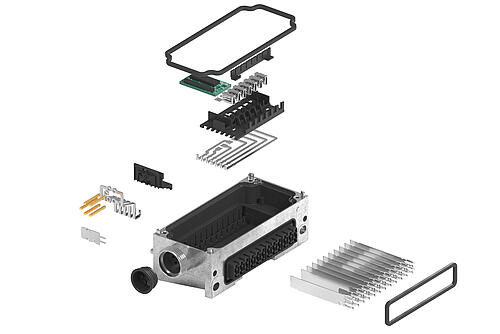

- Termination technology: Screw clamp, press-fit, solder termination

- Rated voltage: 500 V (power), 14 V (signals)

- Rated current: 100 A (power), 5 A (signals)

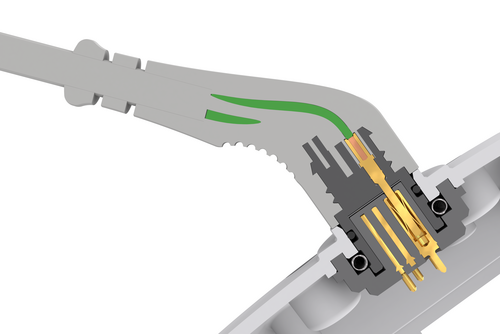

- Special feature: HVIL integration

- Hybrid connector

- Indoor/outdoor

- Pin count: 2 for power, 12 for signals, 2 for the vehicle electrical system

- Degree of protection: Up to IP69K

- Locking: With/without magnet

- Number of mating cycles: ≥10,000 with seal change