In electromechanics, healthcare or ‘health system’ refers to all use cases in which people with health restrictions can be helped through the use of technology. Applications are often found in the fields of prosthetics, orthotics, neurostimulation or mobility.

A key distinguishing characteristic of medical technology is that it does not involve direct or indirect intervention in the human body and does not focus on the sterilisability of the equipment. Rather, it is about the possibility of using adapted technology to make life more comfortable for people with disabilities and also enabling them to use such equipment.

Requirements

A partially electric prosthesis should make walking as realistic as possible for the wearer. There are sensors and actuators in the prosthesis designed for this purpose, which can convincingly imitate the responses of the autonomic nervous system.

As it is being used, the prosthesis compensates for all the effects created by shifting weight, uneven ground or movement. Using it feels extremely natural to the user, as the autonomic nervous system also assumes this ‘job’ unconsciously.

In this specific case, the customer needs a connection system that can be plugged in safely and with little effort. It must be usable outdoors and also still be safe to use even if the user has limited visual abilities.

The general conditions are thoroughly analysed and included in the planning during a detailed meeting with the customers.

Main focal points

The following additional focal points were determined as a basis for finding solutions:

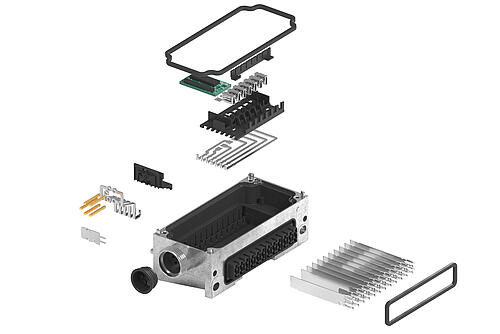

In order to ensure that the equipment can be plugged in frequently (1–5 times per day), at least 10,000 mating cycles are assumed for an average utilisation period of five years.

Plugging in the equipment should not result in any changes in the plug-in behaviour (plug-in force and tightness) or in the electrical application (contact resistances) during the utilisation period.

Approach

How are approaches and requirements pursued in a structured way?

Requirements and influencing factors are analysed, evaluated and taken into account when finding solutions, all according to the Ishikawa principle. This methodology usually results in various solution concepts that are presented to the customer. In the end, it’s the customer who decides on the variant that best fits their overall concept.

Solution

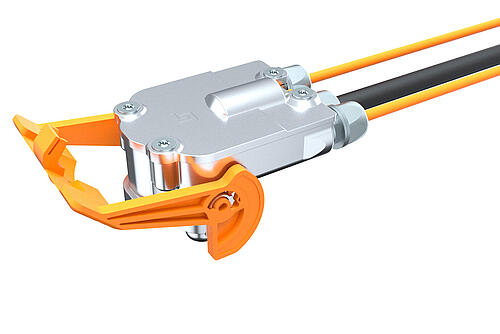

Spring-based locking technology makes it possible to adjust the insertion force and the feel of the connector system with a very high degree of precision. This makes using the connector system considerably more comfortable. Even users with limited visual abilities can use the system safely and with little effort.

You provide the idea – we develop the best possible solution.

In the early phases of pre-development, binder solutions provides support for your project up until its completion. Our goal is to bring your product to market as quickly as possible. Thanks to our extensive value creation structure, we are able to utilise the wide-ranging competencies of the binder group and provide you with full-service support in every phase of the product development process. For optimal results, we use the latest methods and reliable manufacturing processes.

Our experts are able to develop appropriate laboratory tests up to and after series production, carry out component analyses and help you secure international approvals and release recommendations. Combined with our years of project management and design experience, we are able to respond iteratively to any changes as they come.

We look forward to the opportunity to demonstrate and win you over on the high quality and efficiency of our processes that are tailored to each customers’ needs.